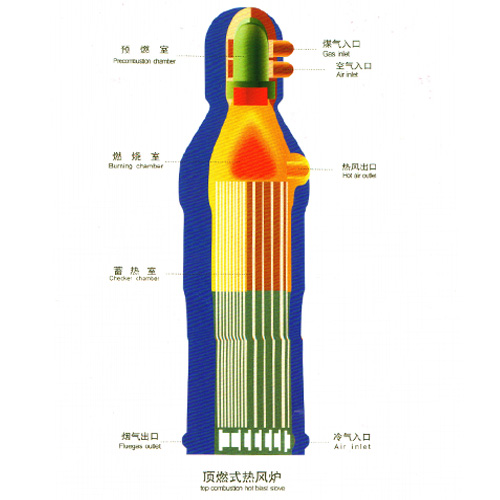

Top fired hot blast stove means that the burner is installed on the top of the hot blast stove of the iron-making equipment and burns in the vault space without a special combustion chamber, also known as a non-combustion chamber hot blast stove. The gas is directly introduced into the vault space for combustion. In order to ensure good mixing and complete combustion of the gas and air in a short period of time, it is necessary to use a short flame or flameless combustion burner with a large combustion capacity. flame burner.

Due to the high hot air outlet of the top fired hot blast stove, the installation plane of the hot blast main pipe is required to be high, so the structural strength of the pillar is required to be high, so the hot blast stove is arranged in a rectangular combination plane. top combustion hot blast stove require mechanization and automation for operation, maintenance, and installation because the burner and hot blast valve are all located on the top platform.

In addition, because these water-cooled valves are installed at a high elevation, the water supply pressure of cooling water is required to be correspondingly increased for the use of large-scale top fired hot blast stoves. The key lies in the design of high-power, high-efficiency short-flame burners. The top-fired hot blast stove absorbs the advantages of internal combustion and external combustion hot blast stoves and overcomes some of their shortcomings. Its structure can adapt to the requirements of high temperature, high pressure and large-scale development of modern blast furnaces, and the combustion capacity can meet the production requirements at the same time. , successfully reduced a lot of equipment, easy production operation and management.

Structural features of top fired hot blast stove:

(1) Scientific structure and high thermal efficiency.

(2) The combustion method of the coal-fired hot blast stove adopts a combination of mechanized chain grate and new energy-saving combustion arch, which has the characteristics of wide adaptability of coal types and sufficient combustion.

(3) The degree of mechanization is high, and the operation is simple and convenient.

Top fired hot blast stoves have become the mainstream products on the market today because of their low furnace body, high air temperature, small footprint, low investment and fast production. Therefore, it represents the development direction of a new generation of high temperature hot blast stoves.